Ammann is focused on driving the further development of process engineering and process technology to

meet the ever-growing demands from markets in various regions with regard to the use of reclaimed asphalt,

emission reductions and plant mobility. Today, the world market leader is the only manufacturer with the plant

technology to produce new asphalt from 100% recycled asphalt. Ammann also offers appropriate recycling

upgrades for every specific demand raised by customers and the markets.

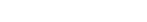

This has resulted in completely new and innovative mixing plant concepts such as the Universal HRT

(High Recycling Technology), a plant concept presented by Ammann that consistently aligns the entire asphalt productionprocess with the maximum possible use of reclaimed asphalt. Or the UniBatch range that combines high flexibility,extendibility and a large selection of variants with modularity, energy efficiency and reduced emission values.

Ammann is also setting new standards in the field of mobility with two new plant types. The EasyBatch II range

for batch asphalt production and the Prime 140 for continuous production processes both stand for maximum

compact mobility coupled with the greatest possible output of 140 tonnes per hour.

All of the Ammann plant ranges share the same core concept: all components in Ammann plants that have an

influence on the quality of asphalt production are proprietary developments manufactured at Ammann facilities

in Switzerland (core components) and the downstream facilities in Germany, Italy, China and in future also

Brazil.

New technological developments in the field of control and routing systems, low temperature asphalt, energy

consumption, wear materials and alternative fuels make it possible for Ammann to offer its customers a decisive

ecological difference for both new plants and plant upgrades whilst guaranteeing the greatest possible productivity

at any time and anywhere around the world.

AMMANN

Articole similare

Reportaj Titan Machinery – SYMMETRICA

Reportaj realizat de Bogdan Constantin PR & Communication Specialist…